Batana oil, often referred to as “liquid gold,” is a highly sought-after oil known for its incredible benefits for hair, skin, and overall wellness. But where does this oil come from, and how is it extracted? In this article, we will take a deep dive into the origin of batana oil, the methods used to extract it, and what makes one method better than another.

What Is Batana Oil Extracted From?

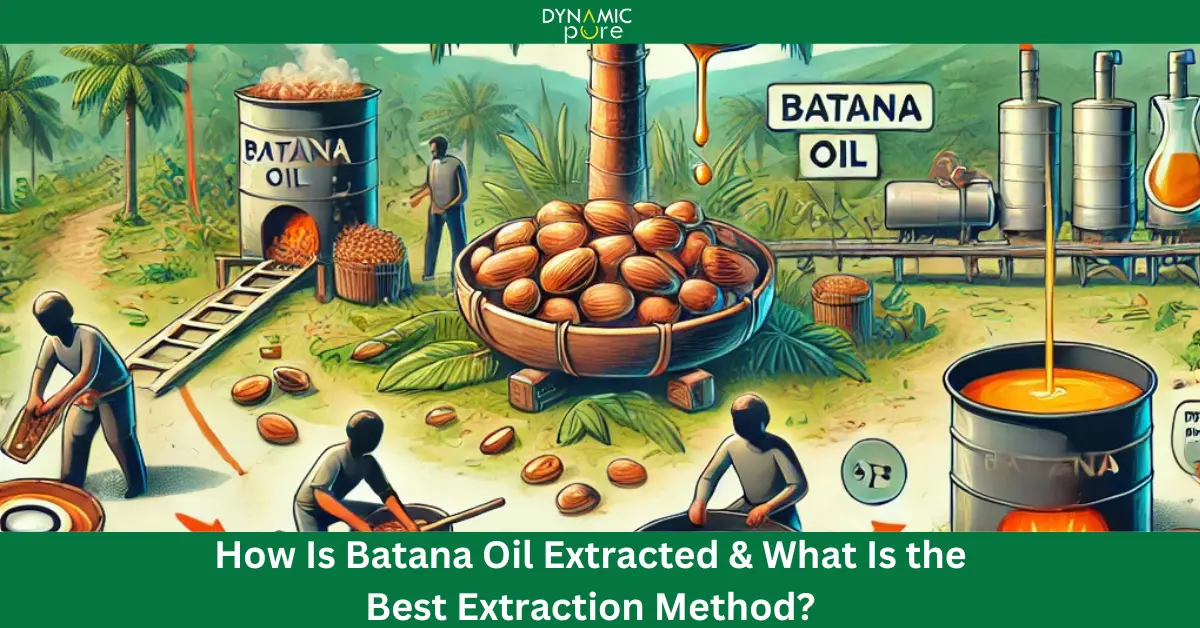

Batana oil is extracted from the seeds of the American oil palm tree (Elaeis oleifera), which is native to Central and South America, particularly the rainforests of Honduras. The oil palm tree produces fruits containing kernels that are rich in oil.

The indigenous Miskito people of Honduras have been harvesting these kernels for centuries to produce batana oil. Due to its rich composition of fatty acids and antioxidants, batana oil has become a popular ingredient in natural beauty and wellness products.

How Is Batana Oil Extracted?

The process of extracting batana oil is labor-intensive and often done by hand using traditional methods. The kernels of the oil palm fruit are harvested, processed, and refined to produce the oil. There are different methods of extraction, ranging from traditional techniques to more modern mechanical or industrial methods. Here’s a breakdown of the extraction process:

What Is the Process of Extracting Batana Oil?

1. Harvesting and Preparation

- The process begins with harvesting the ripe fruits of the oil palm tree.

- The fruits are then boiled or steamed to soften their outer layer, making it easier to remove the kernel.

2. Kernel Extraction

- After boiling, the fruit pulp is separated from the inner kernel. This is typically done manually by cracking open the hard shell.

- The kernel is then cleaned to ensure no residue is left from the pulp.

3. Traditional Oil Extraction

- The cleaned kernels are roasted over low heat to enhance oil release and to develop the characteristic nutty aroma of batana oil.

- Once roasted, the kernels are pounded or ground into a paste.

- The paste is then boiled with water. The heat causes the oil to separate from the solid material and float to the surface, where it can be skimmed off.

- The skimmed oil is further refined through filtering or decanting to remove impurities.

4. Modern Mechanical Extraction

- In modern setups, cold-press machines are used to extract oil from the kernels. This method involves crushing the kernels at low temperatures to preserve the oil’s nutrients and integrity.

- After pressing, the oil undergoes filtration to remove sediments or impurities.

5. Industrial Solvent Extraction (Rare for Batana Oil)

- Although uncommon, solvent extraction can be used for batana oil. This involves the use of chemical solvents to extract the oil from the kernels. However, this method may compromise the oil’s natural properties and is not preferred for high-quality, natural batana oil.

Best Batana Oil Extraction Process

Traditional Extraction: A Cultural Treasure

The traditional method of extracting batana oil remains the most revered for its authenticity and preservation of nutrients. While it is labor-intensive, the indigenous Miskito people ensure that the oil maintains its natural properties, making it highly beneficial for hair and skin.

However, traditional extraction may not be feasible for large-scale production due to its time-consuming nature and manual effort.

Cold-Press Extraction: The Ideal Modern Method

Cold-press extraction is considered the best modern method for batana oil. Here’s why:

- Nutrient Preservation: This method involves low temperatures, which helps retain the oil’s essential nutrients, antioxidants, and fatty acids.

- Efficiency: Cold-press machines allow for higher efficiency and consistency in oil production.

- Purity: The oil produced through cold pressing is pure and free from chemical residues, making it ideal for cosmetic and health applications.

Hybrid Approach: Combining Traditional and Cold Press

Some producers combine traditional roasting techniques with modern cold-pressing to capture the nutty aroma and flavor of traditionally extracted batana oil while ensuring modern efficiency and nutrient retention.

Key Factors in Choosing the Best Method

When determining the best extraction method for batana oil, several factors come into play:

- Nutritional Quality: Methods like cold pressing ensure that nutrients remain intact.

- Scalability: Traditional methods may not be scalable for larger markets, while mechanical extraction can produce higher volumes.

- Purity: Avoiding methods involving chemical solvents ensures the oil remains natural and safe for use.

- Sustainability: Ethical and sustainable harvesting methods protect the environment and support indigenous communities.

Conclusion

Batana oil, derived from the kernels of the American oil palm, is a prized natural resource with versatile uses. While traditional methods remain deeply rooted in cultural practices, modern cold-press extraction is emerging as the preferred method for large-scale production without compromising the oil’s quality.

For consumers seeking the highest-quality batana oil, look for products that emphasize traditional or cold-pressed extraction techniques. This ensures that the oil retains its natural properties and delivers the maximum benefits for hair, skin, and wellness.

By understanding how batana oil is extracted, we can better appreciate the labor and care involved in producing this remarkable oil, as well as support sustainable and ethical production practices.